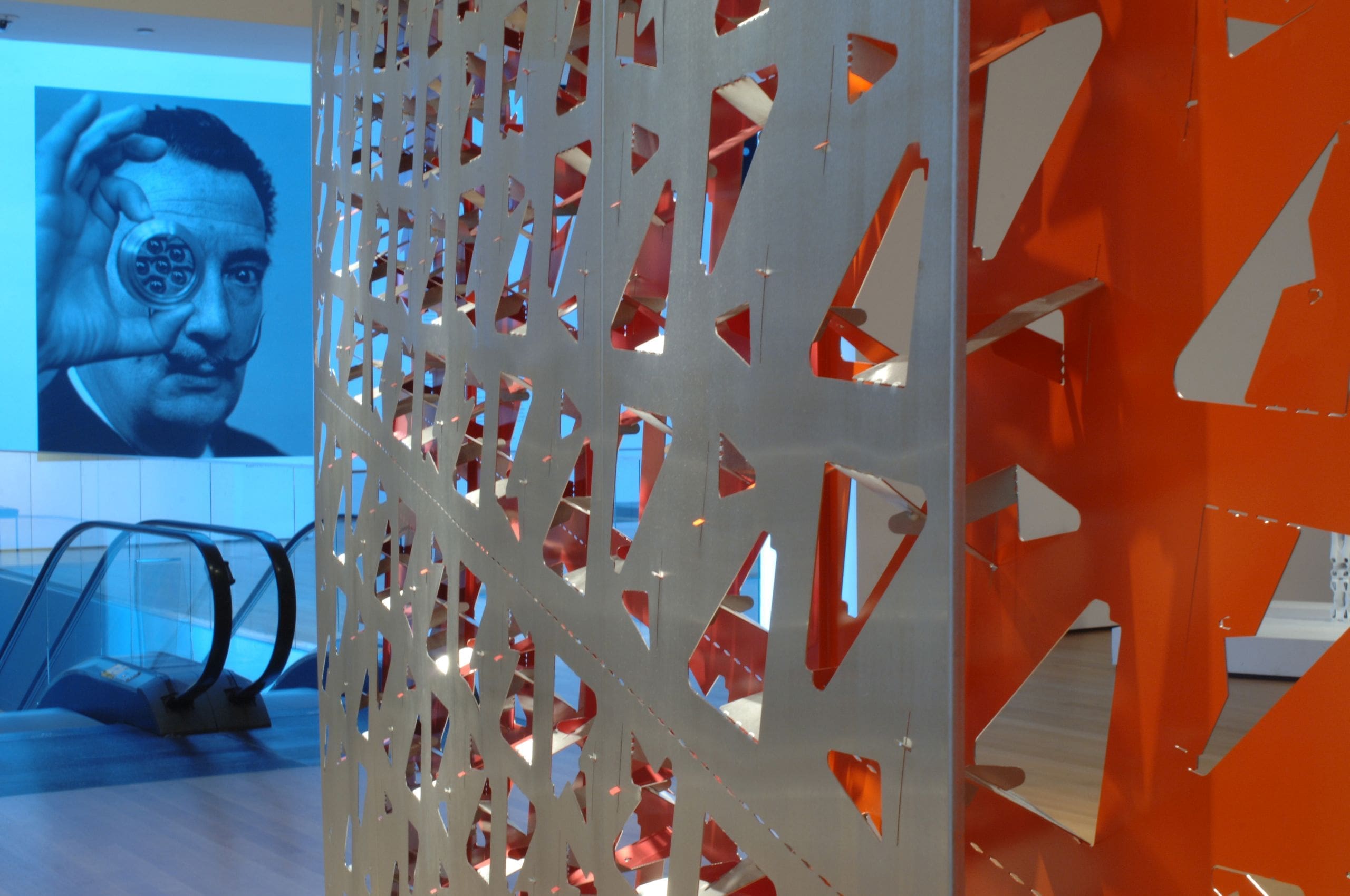

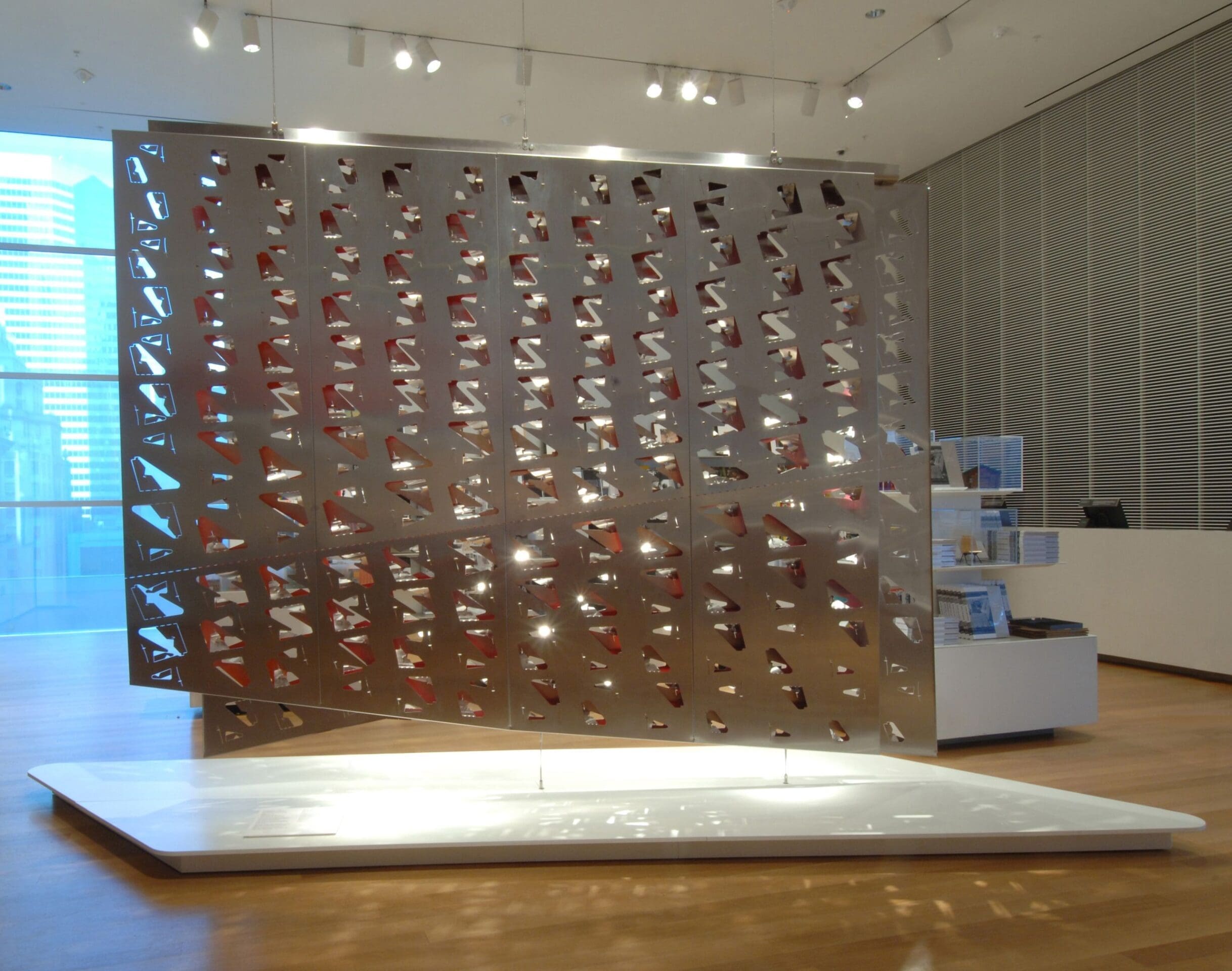

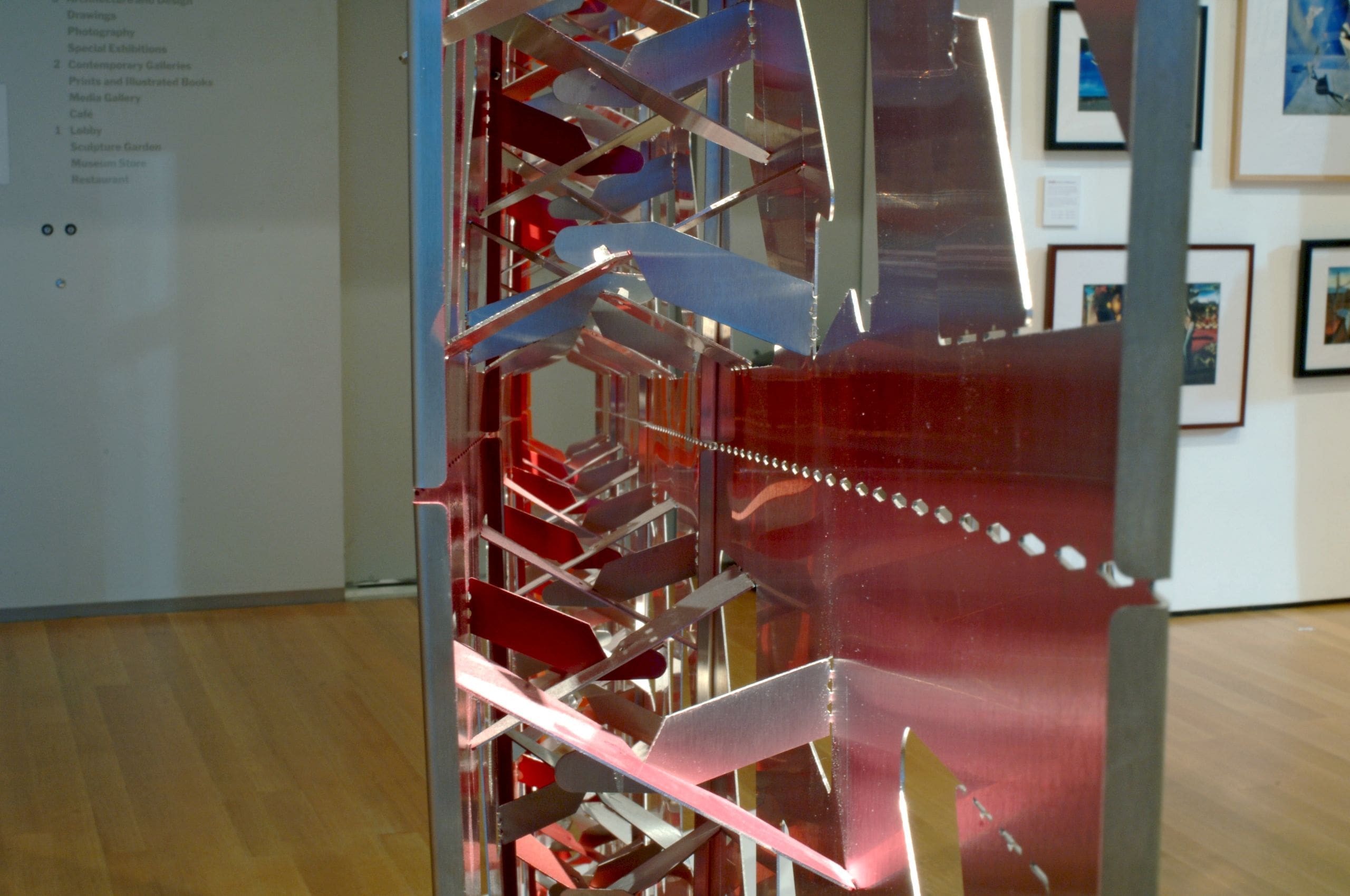

Flatform

Home Delivery: Fabricating the Modern Dwelling

Flatform combines the constraints of material properties and pre-manufactured sizes with the flexibility of digital production processes to explore new logics of design and assembly.

Architectural details are largely a product of the relationship of design to industry. If the modernist detail was based on negotiating tolerances (differences) between pre-manufactured, standardized building components through separate systems of fastening, today we are shifting to methods of production that are based on the management and organization of information, where details, tolerances, and assembly logics are numerically controlled and fully integrated during design. In this context, CNC (computer numerically controlled) systems bring the process of design closer to the production of buildings, merging them through a common language of information.

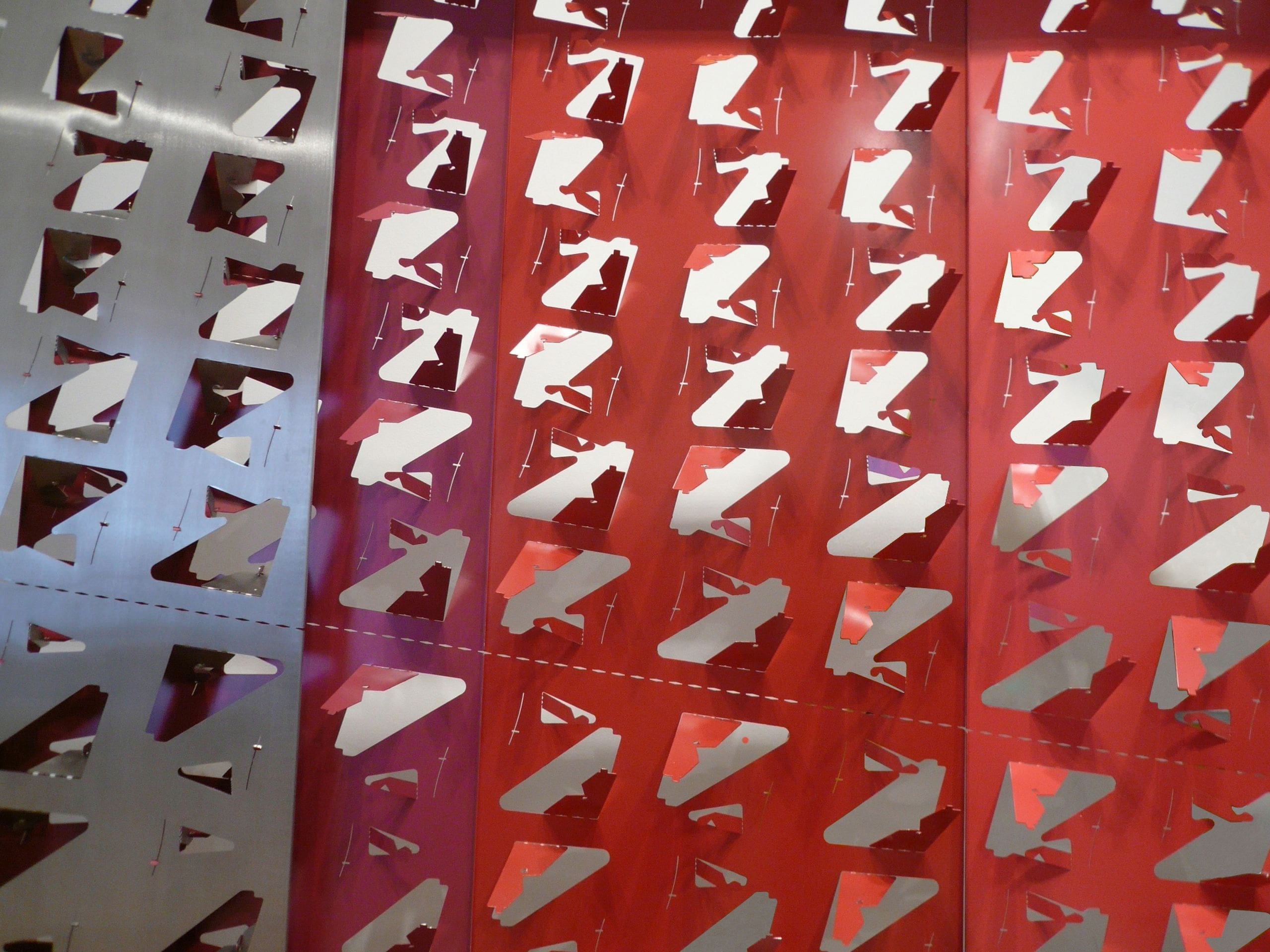

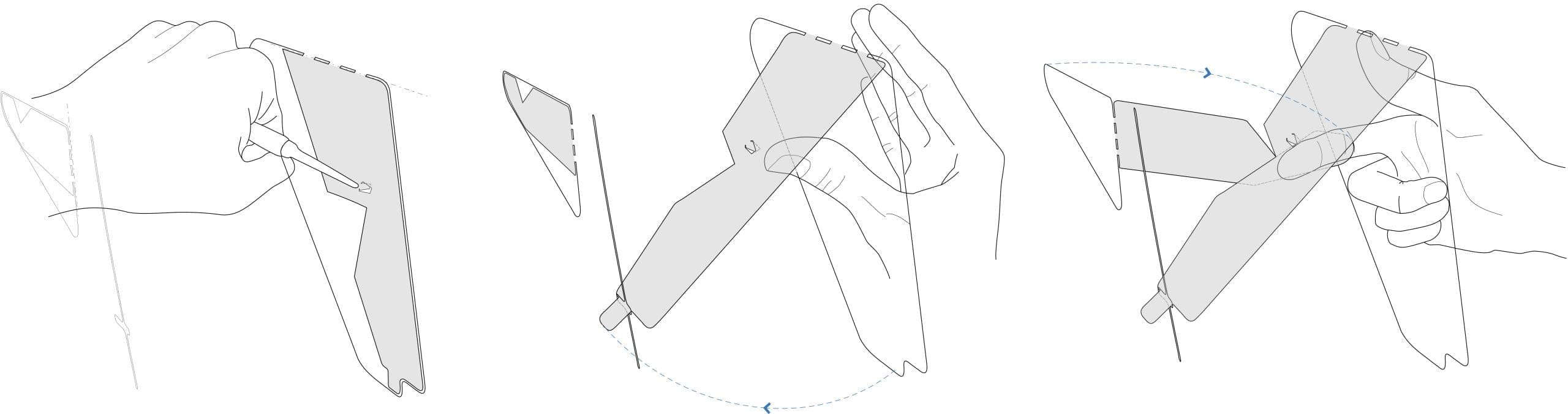

Flatform is a panel system of flat stock stainless steel components that are cut, scored, and folded to form details of assembly without external fasteners. Facing panels are joined through the face of the opposite panel. The surface geometry of each panel is parametrically linked to the characteristics of the tabs and is limited by the ability of the material to bend. The composition and number of tabs can vary to address specific performance requirements.

Location

New York, NY

Client

Museum of Modern Art

Year

2008

MFA Design Team

Scott Marble, Karen Fairbanks, Robert Booth, Adam Marcus, Zachary Aders, Alexis Coir, Milan Dale, Jennifer Downey, Mallory Shure, Rodrigo Zamora, Darren Zhou

Project Sponsors

Maloya Laser, Inc. (Metal Fabrication); NCEEC Corporation (Finishing)

Expanded Alliances

AARDVARK (Technical Design); Stevens Institute of Technology, Product Architecture and Engineering Program, Justin Nardone (Digital Modeling)

Photography

Jongseo Kim; Marble Fairbanks